Feature

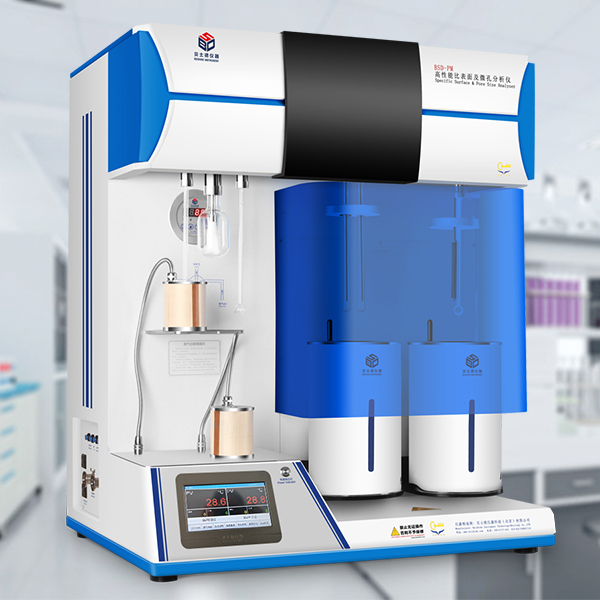

- 2 pretreatment sample degassing stations, 1 sample analysis station, 1 P0 test site, 2 independent cold traps;

- Degassing system and analyzing system independently operate;

- Automatically and intelligently test without manual guarded, friendly voice prompt;

- BEST manifold module, ensure the vacuum and stability;

- Independent high-precision saturated vapor pressure (Pₒ) real-time test station;

- Saturated vapor pressure spiral Pₒtube: spiral Pₒ tube connected with the instrument host, obtain the liquid Nitrogen temperature faster, making the tested saturated vapor pressure closer to the real value;

- Double cold traps to protect the vacuum system and molecular pump;

- Filter bag developed independently by BSD Instrument, eliminate the pollution from internal structure of the instrument;

- Degassing: 2/4/8 optional pretreatment ports, fully automatic program control, timed start, automatic start and stop of vacuum pump, programmed temperature heating, timed end;

- Intelligent self-test process, intelligently judge whether sample tube installed, tube jacket tightened and gas leak or not;

- Automatic capping: Effectively reduce the volatilization of liquid Nitrogen;

- Detailed instrument operation log display and record, can be accurate to the second, the whole experimental records can be traced.

- Prevent accidental “safe fall” intelligent control of liquid nitrogen cup, completely avoid the gas expansion and the danger of sample tube burst because accidental fall of cup;

- Intelligent dual-mode gas injection control, improve the experimental efficiency under the premise of guaranteeing the experimental precision;

- Independent 4 gas pipelines inlet;

- Large-capacity and small-diameter Dewar, keep warm for more than 140 hours, no need to add liquid Nitrogen for 96 hours of continuous test;

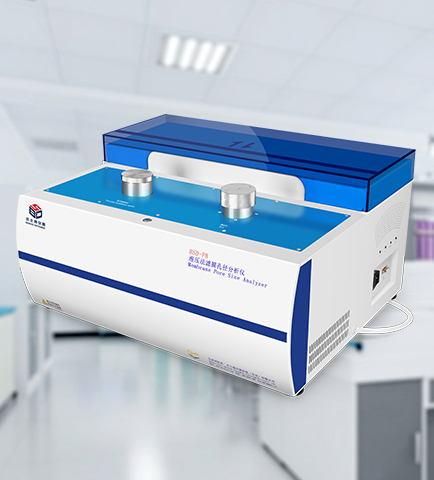

- Dual-station microporous test function (Optional);

- Multi-component competitive adsorption IAST theoretical model;

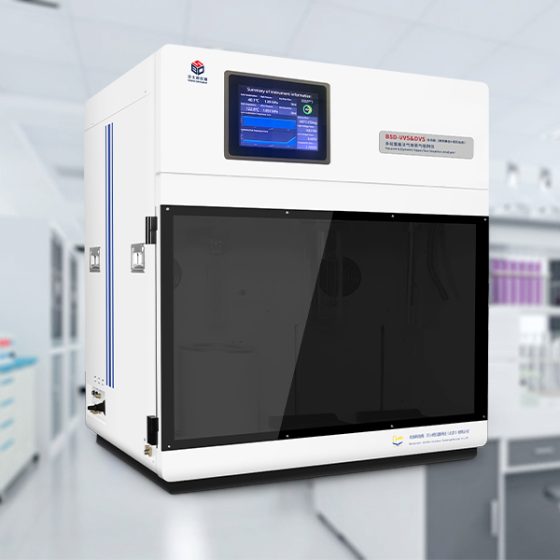

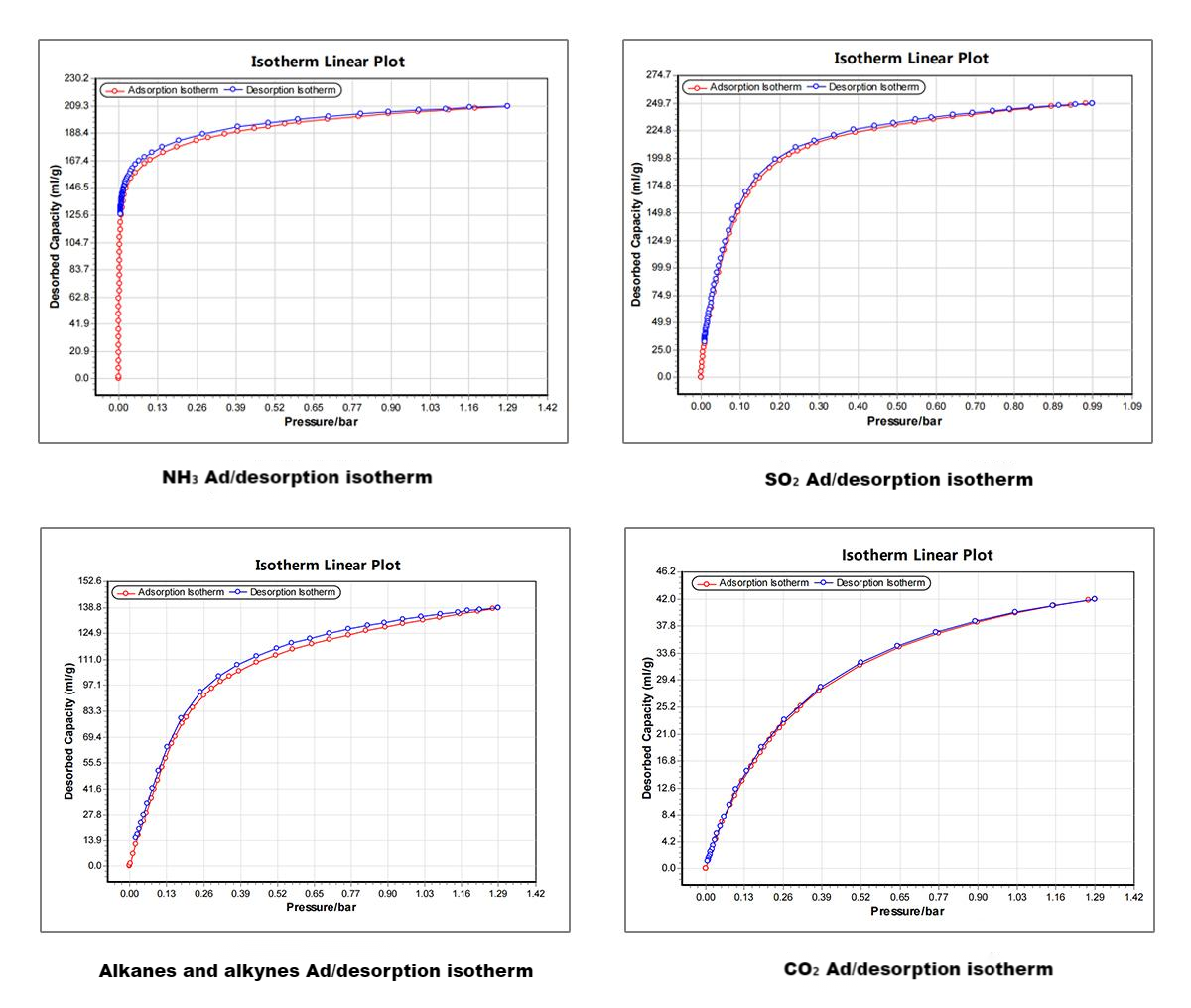

- Pressure sensor: more than 2 pressure sensors for each test site, test accuracy better than ±15%, resistant to sulfur dioxide, ammonia and other corrosive gas;

- Gas pipeline joint: VCR hard connection and corrosion resistant;

- Pretreatment: pretreatment temperature range from room temp to 673K (400 centigrade), 0.1 centigrade temp control precision;

- Vacuum system: equipped with two-stage mechanical vacuum pump and molecular pump, molecular pump pressure can reach 1E-6Pa, make sure P/Pₒreach 1E-8;

- High-quality gas control valve and solenoid valve combination, eliminate gas thermal expansion because of heat generation caused by single solenoid valve;

Main Function

- Ad/desorption isotherm (Static method);

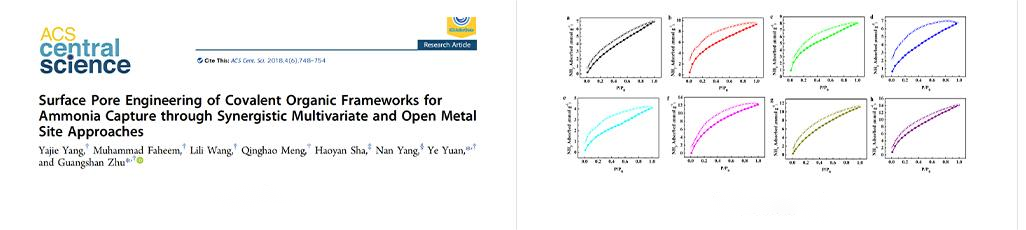

- Strong corrosive gas adsorption(eg. NH₃, SO₂and etc);

- Alkanesand alkynes adsorption (eg CH₄, C₂H₄, C₂H₂ and etc);

- Regular gas adsorption (eg N₂, CO₂, Ar and etc);

- BET surface area and pore structure;

- Ad/desorption thermal determination;

- IAST competitive adsorption simulation;

Application test report

Application Released Paper