- 02um-500um(Gas-liquid method)

- 5nm-50nm(Liquid-liquid method)

- Pressure boosting range: 0~500PSI, pressure regulation accuracy ±02PSI;

- Gas flow range: 0~1L/min, accuracy ±5ml/min; 0-200L/min, accuracy ±0.1L/min;

- Liquid flow range: 0~1000g/min, accuracy ±01g/min;

Test Principle

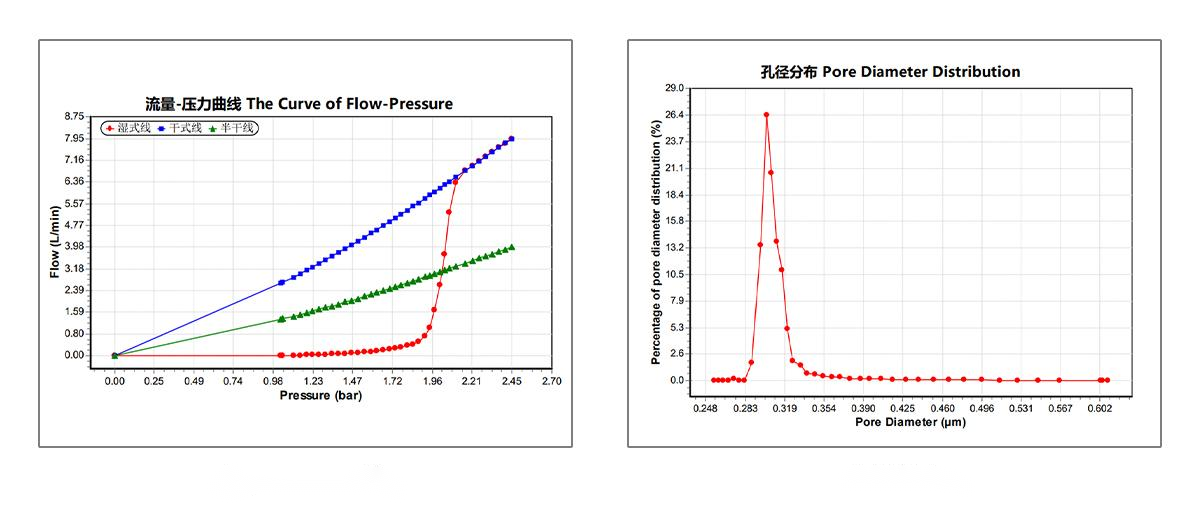

- Gas liquid displacement (bubble pressure method):Apply pressure difference on both sides of the membrane to overcome the surface tension of the infiltration liquid inside the membrane pore channel, drive the infiltration liquid to pass through the pore channel, and obtain the pore size data of the through-hole throat of membrane materials. This method is also a standard method for ASTM thin film measurement.

- Liquid-liquid displacement method:After infiltrating the filter material to be tested with a completely saturated solution, a liquid that is not miscible with the infiltration solution is used as the displacement fluid. Then, the infiltration solution is displaced out of the through-hole channel to obtain liquid flow rate and pressure data. According to the Washburn formula, the pore diameter data of the filter material is obtained. Due to the much lower interfacial tension between liquid and liquid compared to gas-liquid displacement method (bubble pressure method), the liquid-liquid displacement method can test filter materials with smaller pore sizes.

- The relationship between pore size and pressure is shown in the Washburn formula:D=4γCosθ/p

- In the formula:D=pore diameter;γ=Surface tension of liquids ;θ=contact angle;p=differential pressure

- Flow percentage of pore size distribution: f(D) = – d[Fw/Fd)x100]/dD

- In the formula:Fw=Wet sample flow rate;Fd=Dry sample flow rate

Specific model

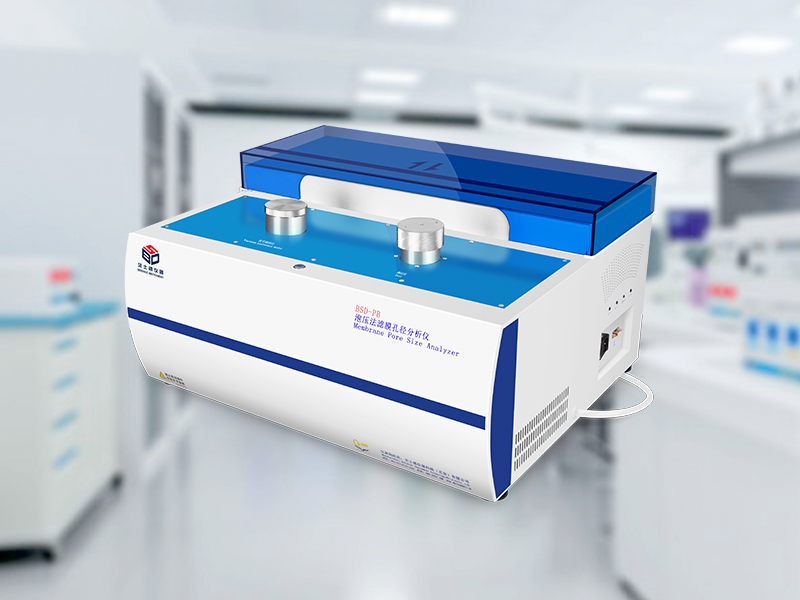

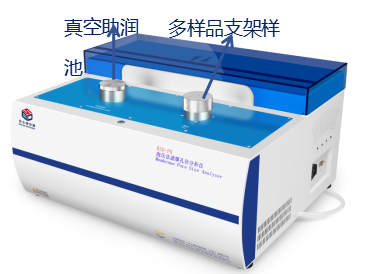

- BSD-PBBubble Pressure Method Membrane Pore Size Analyzer

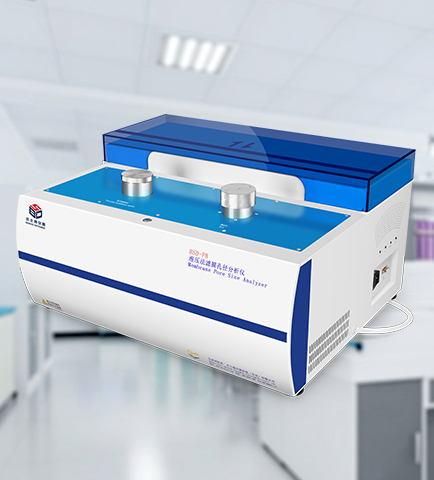

- BSD-PBLFull Function Membrane Pore Size Analyzer

- BSD-PBB Bubble Pressure Method Membrane Pore Size Analyzer

Application Fields

Throat testing of through-holes materials:

- Filter membranes

- Fiber membranes

- Filter cartridges

- Battery separators

- Fabrics

- Non-woven fabrics

- Paper

- Ceramics

- sintered metals

- Rocks

- Concrete

Test function

- Bubble point pressure

- Bubble point aperture (maximum aperture)

- Minimum aperture

- Average Pore diameter

- Most probable pore size

- Pore size distribution

- Liquid permeability(Liquid liquid method function)

- Liquid flux (liquid liquid method function)

- Wet membrane flow – pressure curve(Wet-type curve)

- Dry membrane flow pressure curve (dry curve)

- Gas permeability

- Gas flux

- Integrity evaluation

- Fibrous membrane rupture pressure

Technical Parameter

- Aperture testing range:02um-500um(Gas-liquid method);5nm-50nm(Liquid-liquid method)

- Diversified product pool design for samples of different sizes, special samples can be designed separately;

- Equipped with a fully automatic vacuum lubrication device, it can greatly accelerate the soaking time and improve the testing efficiency by more than 50%;

- According to the different samples to be tested, various wetting liquids can be selected (special wetting liquid Porofil or other wetting liquids);

- High precision dual flow sensor, segmented flow measurement, complementary range, automatic switching;

- High precision dual pressure sensor, segmented pressure testing, automatic program judgment, automatic switching;

- All stainless steel pipeline, metal hard seal, good sealing performance, high pressure resistance, and corrosion resistance;

- Fully automated and intelligent operation, no need for manual attendance, and friendly human voice operation prompts;

- Detailed instrument operation log display and recording, accurate to seconds, with traceable experimental records throughout the entire process.

Technical Advantages

- Vacuum lubrication device:Beishide’s original automatic vacuum moistening device integrated with the main machine, fast opening and closing structure, for difficult to infiltrate materials, vacuum moistening can be used, which can quickly and efficiently infiltrate the sample, improve the infiltration efficiency, convenient operation.

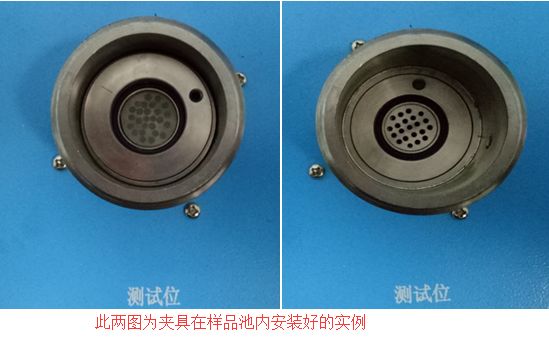

- Multiple sample holder selection:It can adapt to various sizes and types of sample cells, and can test films of different diameters without the need for multiple sample cells. In other words, a single sample cell can test both circular membranes and hollow fiber membranes;

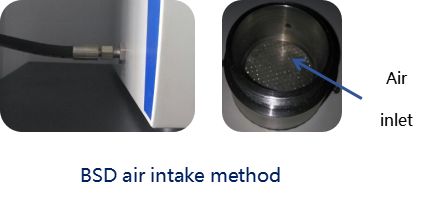

- BSD air intake method:Built in sidewall air intake system is adopted, and the experimental gas extends along the inlet duct set on the sidewall of the sample cell to the top of the sample cell. The sample film is pressurized from the upper direction of the sample cell, and the gas enters from the sidewall of the sample cell, facilitating installation and disassembly, ensuring the air-tightnessof the instrument.

- Other manufacturers’ air intake method:The sample pool structure of the external top intake pipe has many and complicated external components, which leads to the problems of inconvenient use and poor air tightness.

- Pressure sensor(MEAS, USA): Dual pressure sensor,range:0-1bar;0-40bar, precision:±0.05mbar

- Flow sensor(Honeywell, USA):Dual flow sensor,range:0-1L/min;0-200L/min, precision:±0.1ml/min

- Weighing balance(Sartorius, Germany):BSD-PBL is used,range:0-2100g, precision:±0.01g

Data Report

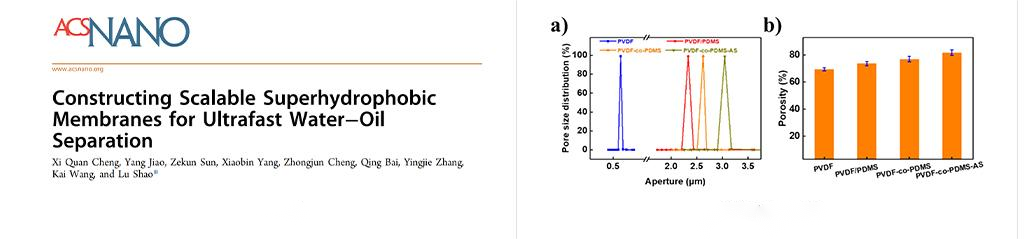

Application released Papers

BET Surface Area pore size,pore volume,microporous,mesoporous,Gravimetric Sorption-Vapor/Gas,High Pressure Gas Sorption,Corrosive Gas Adsorption,Breakthrough Curve,Automatic Chemisorption,Membrane Pore Size,True Density & Porosity,Beishide Instrument Inc.

BET Surface Area pore size,pore volume,microporous,mesoporous,Gravimetric Sorption-Vapor/Gas,High Pressure Gas Sorption,Corrosive Gas Adsorption,Breakthrough Curve,Automatic Chemisorption,Membrane Pore Size,True Density & Porosity,Beishide Instrument Inc.